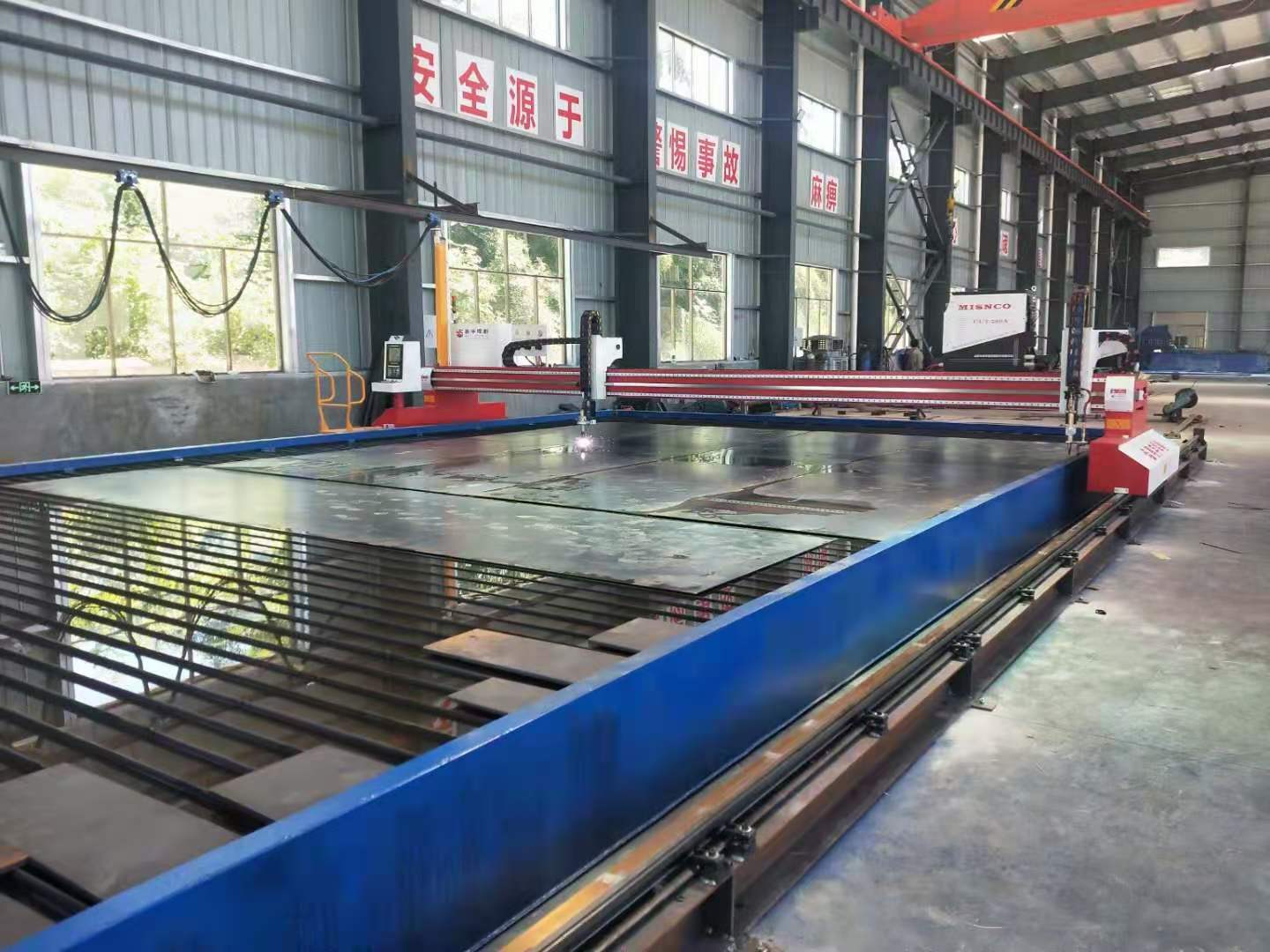

CNC Flame and Plasma Cutting Machine

The cnc plate raw materail flame and plasma cutting shearing machine: The Longitudinal Transmission: bilateral driving to make sure stable running

The Bilateral rack and pinion transmission without engagement gap, make the machine running smoothly when the ground base deformed

Lifting Body: this configuration with low failure rate,easy to detect. Can realize the user's own adjustment if the mobile body tilt after the long time use.

1. 3012 Gantry Plasma&Flame CNC Cutting Machine

2 Pcs torches( 1 plasma(Powermax 105A) +1 flame torch), 2 Pcs lifting up and down device in horizontal direction(X axis).

Shanghai F2300B CNC control system

StartCAM/FastCAM professional version nesting software

1 Pcs HYD THC(Torch Height Controller) +1 Oxyfuel THC(CHC-200F)

1 Pcs Anti-collision device

Plasma Power- Powermax 105A of Hypertherm

Servo motor(Japan Panasonic Original), 2 pcs of 750w in longitudinal; 1 pc of 400w in horizontal.

Reducer-- 3 Pcs is equipped Japan Panasonic servo motors

Automatic Ignition Mode x 1 Pcs

Wood Packaging with load in standard container 1x20ft(LCL)

Gift free consumable(2/3 sets) of nozzles with electrodes

| Model | 3012 Gantry CNC Flame&Plasma Cutting Machine | |

| Machine Size | (W)3000mmx(L)12000mm | Need to Customize Machine for your application |

| Effective Cutting Range | (W)2150mmx(L)10000mm | |

| Cutting method | Plasma(Powermax105A) Flame | |

| Cutting torch | Plasma 1 torch (Powermax105A) Flame 1 torch | |

| Cutting torch lifting distance | 200mm | |

| Cutting Thickness | Plasma: Quality cutting 1--20mm thickness with pierce cutting thickness 22mm thickness, with Maximum thickness 32mm. Flame :6-200mm | |

| Cutting Speed | Plasma 500-3500mm/min Flame 100-1200mm/min | |

| Arc voltage increase | HYD THC | |

| Plasma torch anti-collision system | Yes (One) | |

| Control System | Shanghai F2300B Control system with support 11 kinds of languages, such as Russia, Chinese,English, etc | |

| Drive Mode | Servo motor( Japan Panasonic)--3pcs (Origin) X axis: 400W-1pcs; Y axis :750-2 pcs | |

| Nesting Software | StarCAM/FastCAM nesting software | |

| Longitudinal mechanical transmission | 1 set of precision gear rack | |

| Horizontal pipeline transmission | Fully sealed engineering towline | |

| Longitudinal pipeline transmission | Hanger | |

| Rail length | 12m(total 24m) 2m/section | |

| Heavy rail | 30kg/m | |

| Cutting table | 10m enough for 12m Machine Rails | |

| Accurate Cutting Precision | +/- 0.2mm/m | |

| Machine Moving Speed | 9000mm/min | |

| Positioning speed | 24000mm | |

| Setting up Speed error | ≤±5% | |

| Automatic adjustment of high precision | ≤±1.0mm | |

| Longitudinal straight line accuracy | ±0.3mm | |

The main technical indicators of the machine

| Working Condition |

| Overall accuracy of the whole machine (based on the right comprehensive graphic) Side length (four sides) 1000•³1000, Scribing speed 500-800mm / min | ||

| Side length (four sides) | Mm | ±0.5mm |

| Diagonal Error | AD-BC | | Mm | ±0.5mm |

| Origin Deviation | Mm | ±0.2mm |

| Intersection deviation | Mm | ±0.5mm |

| Straight line deviation | Mm | ±0.2mm |

| Cutting surface quality (roughness) (select δ = 25 sheet) | Rz (um) = 70 + 1.2a roughness 12.5 | |

| Verticality and tilt tolerance | μ (mm) = 0.4 + 0.015a Tool: Angle ruler | |

| Straight angle | Mm | Diagonal error ≦ ± 0.2 mm |

| Walking straightness | Mm/Effective cutting length | Longitudinal ≦ ± 0.2mm / effective length Horizontal ≦ ± 0.2mm / effective length |

| Torch angle error | Degree | ≦ ± 0.5º |

| Equipment noise | Decibel | ≤80dB |

Machine working conditions

| Power Power voltage / frequency | 3X380v±10%/50Hz Single Phase 220v±10%/50Hz |

| Input Power of machine | 3KW |

| Compressed air | Dry, oil-free; Pressure: 0.8Mpa Flow: 1.0m3/H |

| Gas type | Propane\Acetylene\Propene\Natural Gas. |

| Ambient temperature | 0-50 ℃ |

| Relative humidity | <90% Non-Condensing |

| Surroundings | Ventilation. No big impact within 5 meters |

| Earthquake level | According to six levels of defense |

Machine frame is 8mm thick steel plate welded thicker than the other manufacturers, to improve the structural strength and enhance life. make sure the working stable and cutting precision.

English

English Русский

Русский Español

Español العربية

العربية